Home > 제품소개 > 산업용밸브 > 컨트롤 밸브

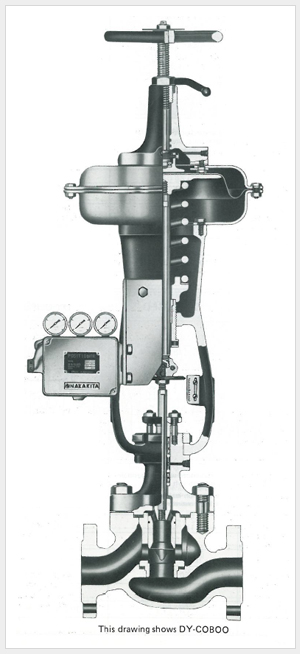

VALVE BODY ASSEMBLY

- The pressure containing part consist-ing of the valve body, bonnet and trim is called the [valve body assembly]. The pressure-temper-ature rating for the materials is determined by the applicable standard. As to the type and size, the optimum selection is made accordin-ing to your [specifications].

- The valve plug, seat ring, cage, guide bushing, valve stem, etc. art called the [trim], and its combination is determined according to your [specifications] including the fluid properties and pressure drop.

- The [flow characteristic] which indicates the relationshop between the valve travel and the flow rate is determined by properly selecting the shape of the throttle portion consisting of the valve plug and seatring.

- The gland packing is required to prevent leakage of the fluid as well as to possess low-friction property and durability. It has a vital role in the normal operation of the control valve.

DIAPHRAGM ACTUATOR

- The [actuator] controls the travel of the valve, via the valve stem, by the valve, via the valve stem, by the balance between the operating air pressure applied to the dia-phragm chamber and the compres-sive force of the counter spring.

- The signal (standard : 0.2 to 1.0kgf/㎠) from a pneumatic indicat-ing controller is normally guidedinto the diaphragm chamber. For further responsiveness, a positioner is installed.

- When the electric signal (4 to 20 or 10 to 50 mA DC) is used, an E/P positioner is used.